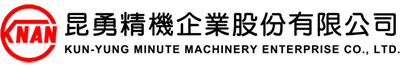

Energy-Saving Type High-Temp. & High-Pressure Low Liquor Ratio Reel-Less Dyeing Machine

Model:KN-NR-C Series

Widespread Applications

Most suitable to (15d ~ 150d) fabrics of natural or synthetic yarns, blended yarns, micro yarns, high-density taffetas, spandex yarns, polyester and nylon of 15d ~ 30d etc.

- Newly designed special nozzles to enable excellent dyeing performances. The reel-less construction enables the nozzle to spray out dye-liquor while actuating the cycling of the fabric to a high speed possible upto 500m/min.

- Adjustable spraying pressure 0.8~3Kg/m2 at the nozzle, the spraying flow brings out the cycling of the fabric to a high speed of 150~500m while producing a homogeneous dyeing environment as well as shortening the cycling time required in a dyeing process.

- Special in-tube netting design helps to reduce water quantity used, so the liquor ratio can be lowered to 1: 3.5~6 according to natures of relative fabrics being dyed.

Speedy Dyeing, High Quality Output

- Most up-to-date constructional design enables 3 times more of the dyeing flow than traditional jet dyeing machines; with fabric speed controllable at 150~500m/min and less liquor ratio at 1: 3.5~6. The fabric cycles at a high speed and in a pressurized condition - to avoid damages caused by folding, chafing, slipping, and breaking, and improve the hand-fell and the softness over the fabric.

- Special designs of uniform-flow inner nets and energy-saving multi-layered rear construction etc help to maintain a stable liquid level in tube - to avoid influences on cycling dye-flows due to a temperature change. Such a stable dyeing environment helps to cycle the fabric smoothly and steadily inside the tube, while effectively prevent any damage over fabric surfaces.

- Special designs for low-ratio liquor-spraying, temperature-degrading, and tube-washing etc enable the success of a uniform dyeing process by saving the time, energy, and chemicals in use.

- Via automatic program controls, all functions such as water filling/draining, temperature up/down, pressurizing, washing, sampling, chemical injecting etc are fully monitored throughout the whole dyeing process. And from a single-machine control to a centralized management, an internet monitoring system etc, we provide full and integral solutions in response to customer's requests for rectifying any abnormality in dyeing process, for cutting losses from human errors etc.

Further Optional Equipments Out Of Our Standard Supplies

- Centralized monitoring & control system.

- Remote dyestuff mixing system.

- Chemical dosing system.

- Fabric-length counter device.

- NaOH-concentration analyzing system for weight-reduction applications.

- PH-value monitoring & control system.

- Fabric plaiting device.

- Inverter for fabric-exiting reels.

- Traversing mechanism for fabric reels.

- Flow gauge for water-filling check.

- Inverter for main pump.

- Dye-liquor spraying device.

- Water-saving type tube-washing device.

- Automatic dyestuff dissolving device.

- Fluff filtering device.

|

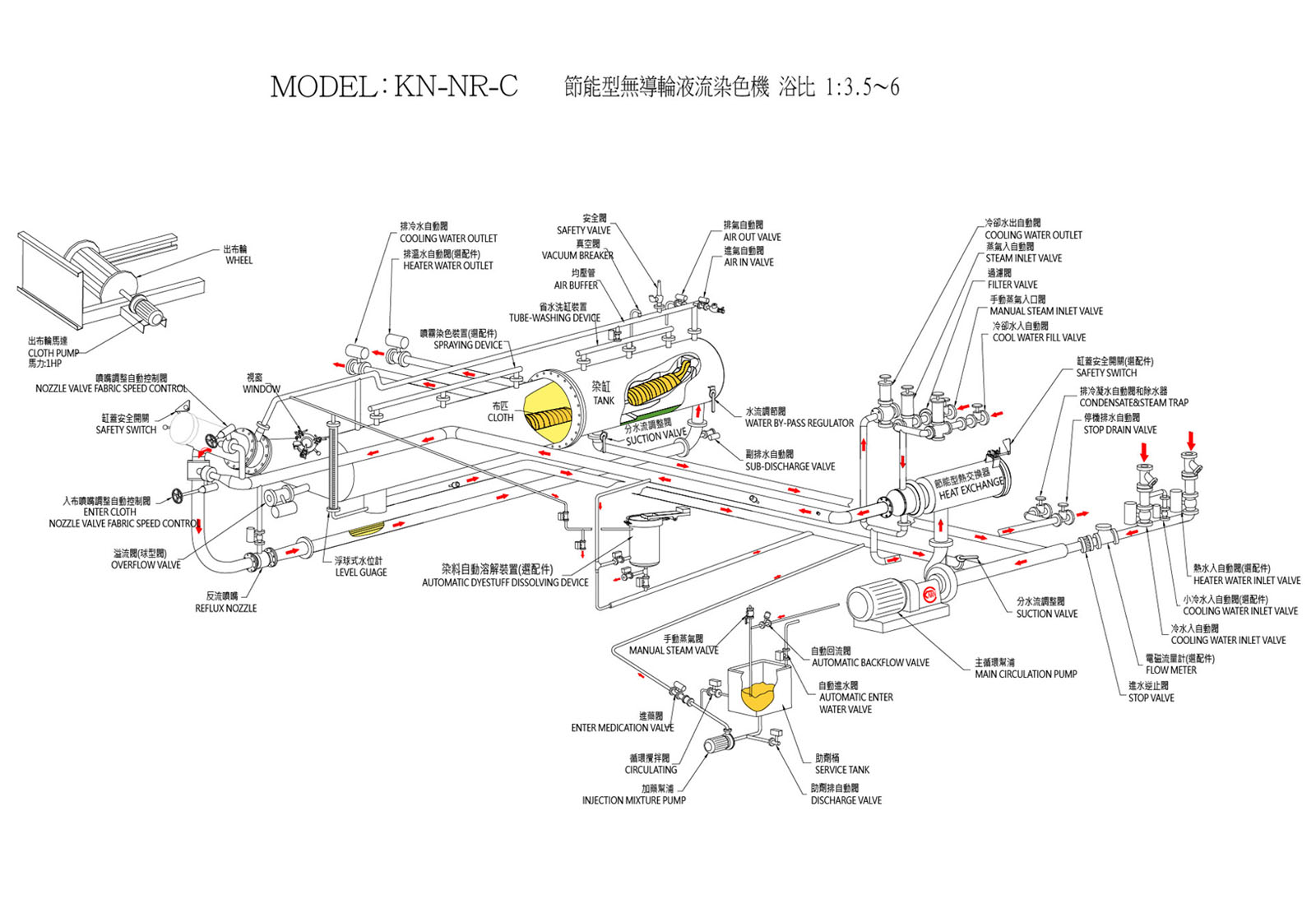

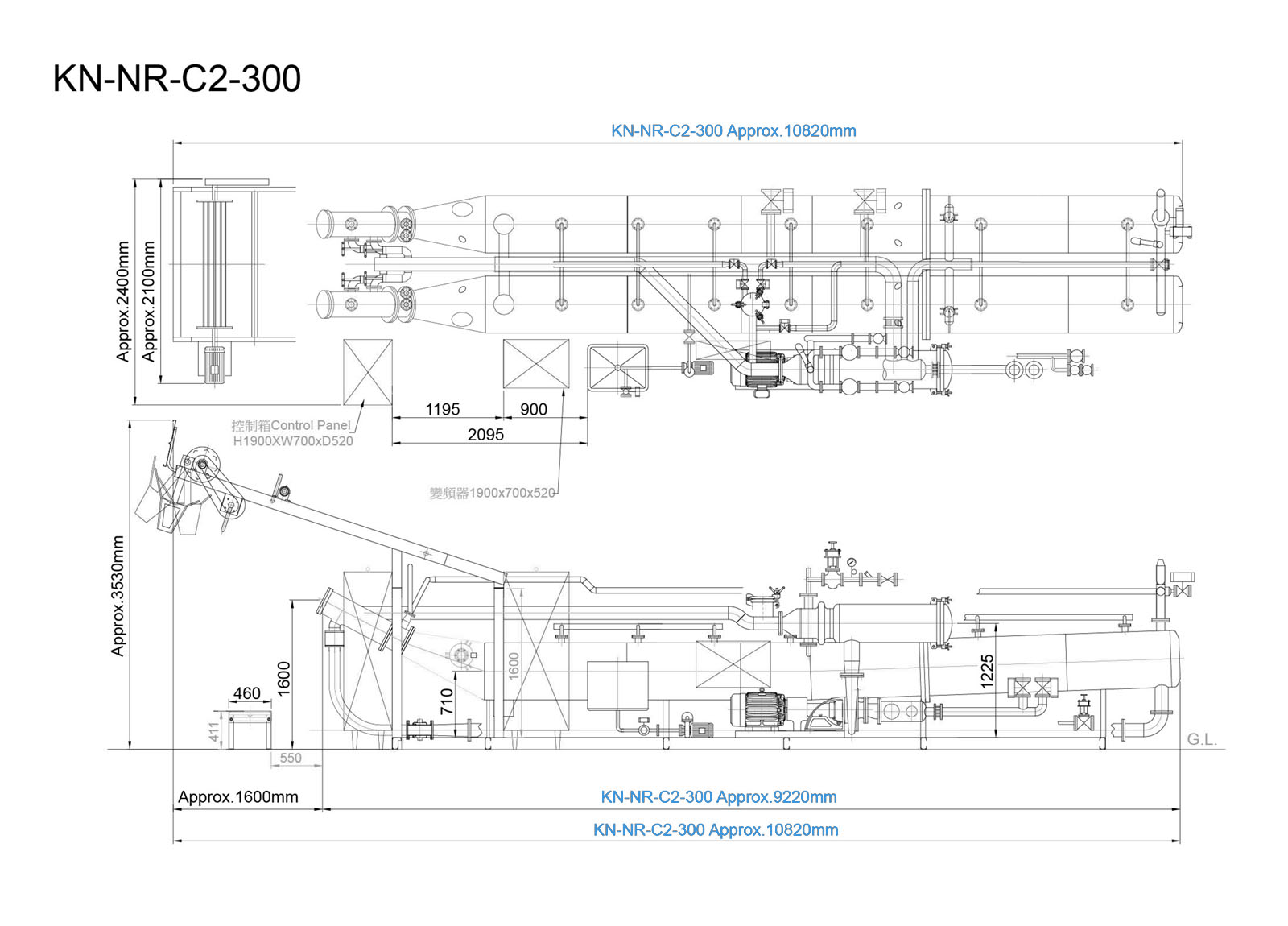

Model

Item

|

Circular NR-C-Series | |||||||

|---|---|---|---|---|---|---|---|---|

| KN-NR-C1-30 | KN-NR-C1-60 | KN-NR-C1-80 | KN-NR-C1-100 | KN-NR-C1-150 | KN-NR-C2-300 | KN-NR-C4-600 | ||

| Max. Pressure | kg/cm² | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Max. Temperature | °C | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Liquor | Lit. | 140~200 | 280~400 | 330~480 | 400~600 | 600~900 | 1200~1800 | 2400~3600 |

| Capacity Weight | kg | 15~30 | 30~60 | 40~80 | 60~80 | 100~150 | 240~300 | 480~600 |

| Thin Cloth Length | m | 150 | 300 | 400 | 500 | 750 | 1500 | 3000 |

| Power | kw | 10~15 | 15~20 | 15~20 | 15~20 | 20~30 | 30~40 | 40~60 |

| Fabric Speed | m/min | 150~500 | 150~500 | 150~500 | 150~500 | 150~500 | 150~500 | 150~500 |

| Heating Rate | min | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Cooling Rate | min | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Cooling Water Consumption | ton | 0.35 | 0.7 | 0.9 | 1.0 | 1.2 | 2.5 | 5 |

| Steam Consumption | kg | 45 | 90 | 120 | 150 | 200 | 400 | 800 |

| Air-Capacity | m² | 1 | 1.4 | 1.6 | 1.8 | 2.0 | 4 | 8 |

*We reserve the right to make amendment without any further notification.

*We reserve the right to make amendment without any further notification.