High-Temperature, High-Pressure Low Liquor Ratio High Speed Dyeing Machine

Model:KN-RS-BB Series

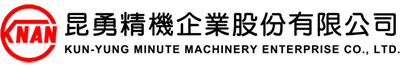

Innovative constuction designed makes following differences compared with conventional jet dyeing machine:

- During processes of high density fabric, the level of dyeliquid comes much more stable due to special dual jacket. By means of optimum slope of tube and water separating device at front enable the fabric to accumulate, expand and slide in smooth order without influencing by timperature.

High Efficiency Productivity

- 15-30% higher loading capacity than conventional jet dyeing machine.

- Fabric circulsted by voluminous flow. Not only increases the productivity but also shortens the dyeing cycles.

- Due to special dual jacket, Min liquor ratio 1:5-10 can be achieved subject to kinds of fabric.

- Lifticg reels driven by torque motor prevent the fabric form being blocked on reels.

High Quality

- Innovative construction makes fabric run faster under low pressure status.(0.5-2.8kg/m²) It can avoid creasing marks, fluffing, slippage and friction marks.

- Stable and constant liquor level can secure better order of accumulation without influencing by temperature.

- Machine adopts an integrated process form holding, heating/cooling gradient, injection, water filling and drainage, pressurized/depressurized rinsing to sampling. Programmable control system are available for individual, remote control and centralized monitor & control system.

Quick Dyeing

- Besides 50-500g/m² woven and knitted fabric (T, T/C, T/R, T/W etc.) also suit for high count yarn. Microfiber, high density fabric, Acetate/rayo,/Nylon plain Taffeta Lycra/spandex, fabric Tencei and its blends and knitting fabric.

- Besides dyeing process, Following optional devices are also available upon requirement:

- Centralized monitor & control system.

- 2nd floor color mixed system.

- Dosing Injection system.

- Fabric lingth counting device.

- Naoh concentration analyzing system for weight reduction.

- PH conductivity monitor & control system.

- Plaiting device for loading.

- Sliding device for loading.

- Flow meter.

- Inverter for main pump.

|

Model

Item

|

Circular RS-BB-Series | |||

|---|---|---|---|---|

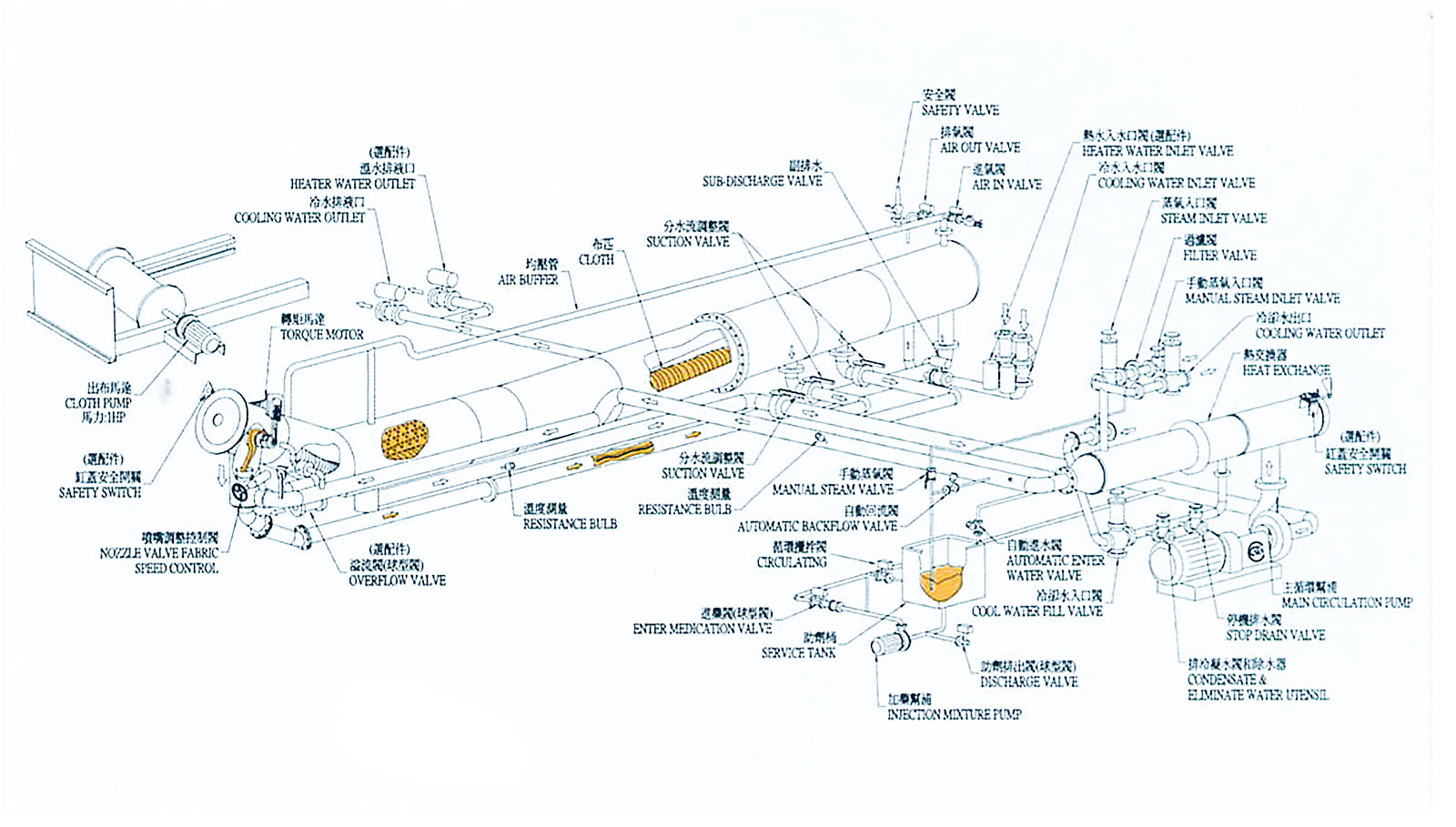

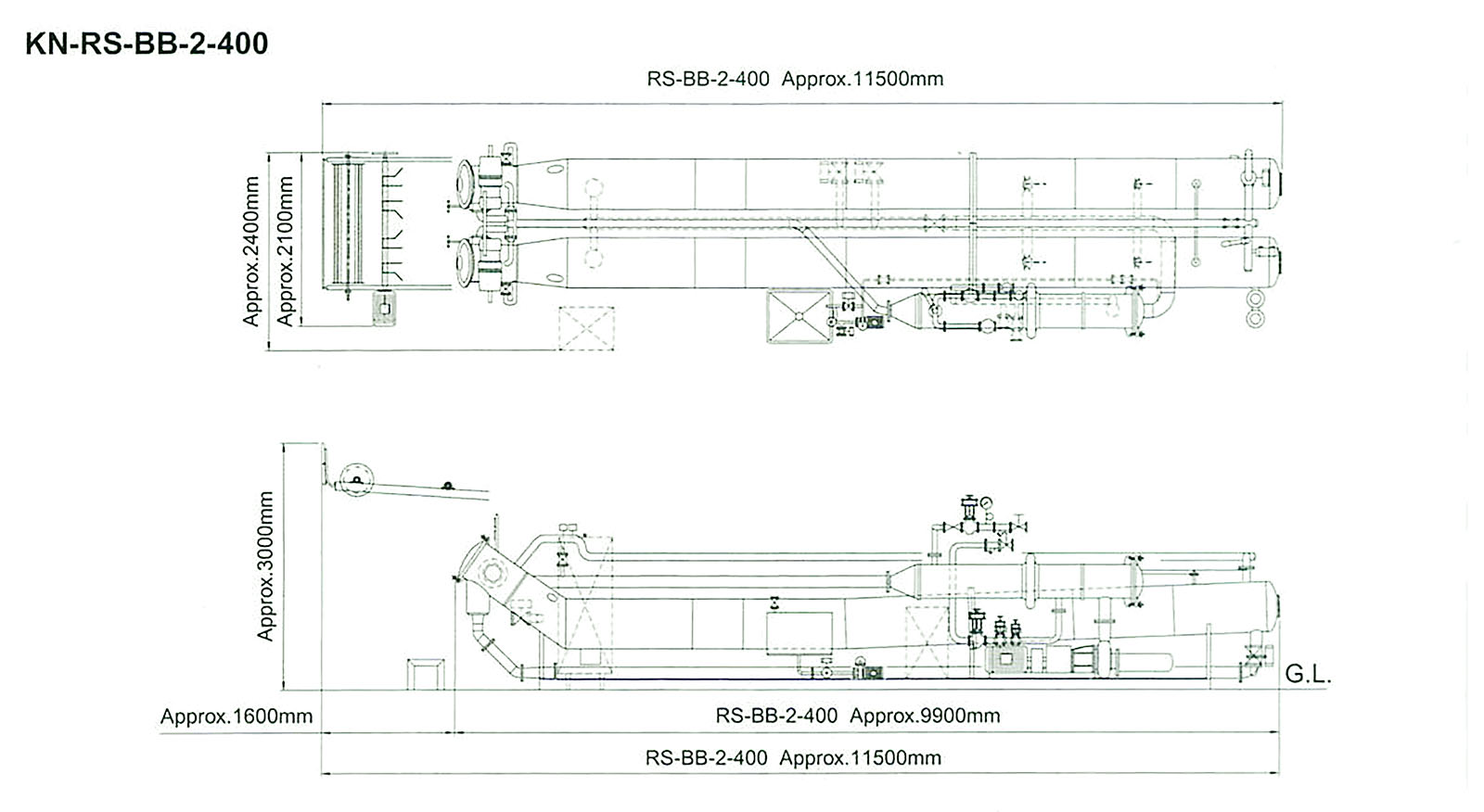

| KN-RS-BB-1-200 | KN-RS-BB-2-400 | KN-RS-BB-4-800 | ||

| Max. Pressure | kg/cm²G | 5 | 5 | 5 |

| Max. Temperature | °C | 140 | 140 | 140 |

| Liquor | Lit. | 800~1400 | 1600~2400 | 3000~4800 |

| Capacity Weight | kg | 120~200 | 240~400 | 480~800 |

| Thin Cloth Length | m | 1000 | 2000 | 4000 |

| Power | kw | 20 | 40 | 60 |

| Fabric Speed | m/min | 150~600 | 150~600 | 150~600 |

| Heating Rate | min | 20 | 20 | 20 |

| Cooling Rate | min | 15 | 15 | 15 |

| Cooling Water Consumption | ton | 1.5 | 3 | 6 |

| Steam Consumption | kg | 250 | 442 | 900 |

| Air-Capacity | m² | 2.2 | 4.4 | 8.8 |

*We reserve the right to make amendment without any further notification.

*We reserve the right to make amendment without any further notification.