High Temperature Automatic Rapid Dyeing Machine

Model:KN-FN-C Series

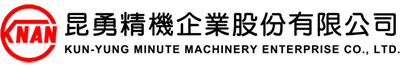

Suitable for fabrics and blends of T, T/C, T/R, T/W etc of natural, synthetic, micro-deniered, high twist, and high density yarns; in weight range of 50-500g/m². The unique "jacketed" construction with special cone-nozzle assembly ensures its high productivity. The lifting reel driven by a torque-motor helps not only to reduce the tensile force incurred during fabric transportation, but also to prevent the fabric from being blocked or tangled over the reel when processing light-weighted fabrics in double-strips. The machine is also useful for fabric relaxing and shrinking applications.

This unique construction enables the machine with following advantages:

High Efficiency Productivity

- 15-30% extra loading capacity than any traditional jet dyeing machine.

- The fabric is circulating under voluminous liquid flow. This not only upgrades the productivity, but also reducesthe dyeing cycles.

- Due to the special jacket construction, a low liquor ratio of 1:5~9(according to types of fabrics )is able to be achieved.

High Quality

- Innovative construction makes fabric run faster under low pressure condition(0.6~2.8kg/m2). This helps to avoid creasing marks, fluffing, slipping, and friction over the fabrics.

- Stable and constant liquor level helps to secure better order of fabric accumulation while freeing from the influence of temperature variation.

- The machine is integrated with a perfect program for processes in holding, heating/cooling gradient, injection, water filling and draining, pressurized/depressurized rinsing, and sampling. A programmable system is available for each independent control,or for a remote and centralized monitoring as well as control system.

Quick Dyeing

Liquor flow is three times faster than that of a traditional water-spray type dyeing machine. The speed range is variable from 50~500 g/minute to suit to different fabrics-while under a liquor ratio of 1:5~9.

Further to a standard dyeing process,the following options could also be included in accordance with your request:

- Centralized monitoring & control system.

- 2nd floor color-mixing system.

- Dosing injection system.

- Fabric-length counting device.

- NaOH-concentration analyzing system for weight reduction purposes.

- PH conductivity monitoring & control system.

- Fabric plsiting device.

- Inverter for fabric lifting reels.

- Traversing mechanism for fabric reels.

- Flow-rate gauge.

- Inverter for main pump.

- Dye-liquor spraying device.

- Water-saving type tube-washing device.

- Automatic dyestuff dissolving device.

- Fluff Filtering Device.

|

Model

Item

|

Circular FN-C-Series | Circular FN-C-L-Series | ||||||

|---|---|---|---|---|---|---|---|---|

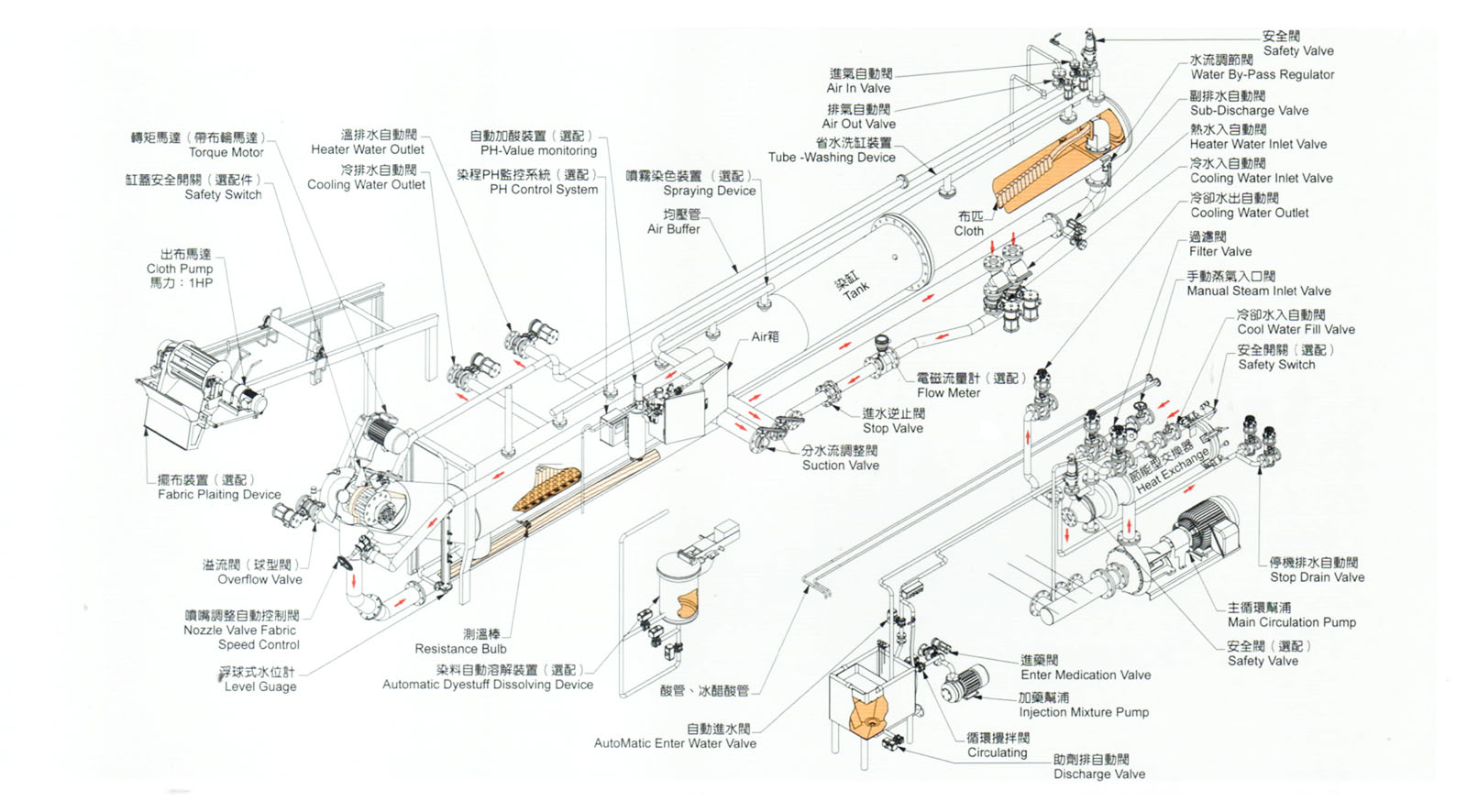

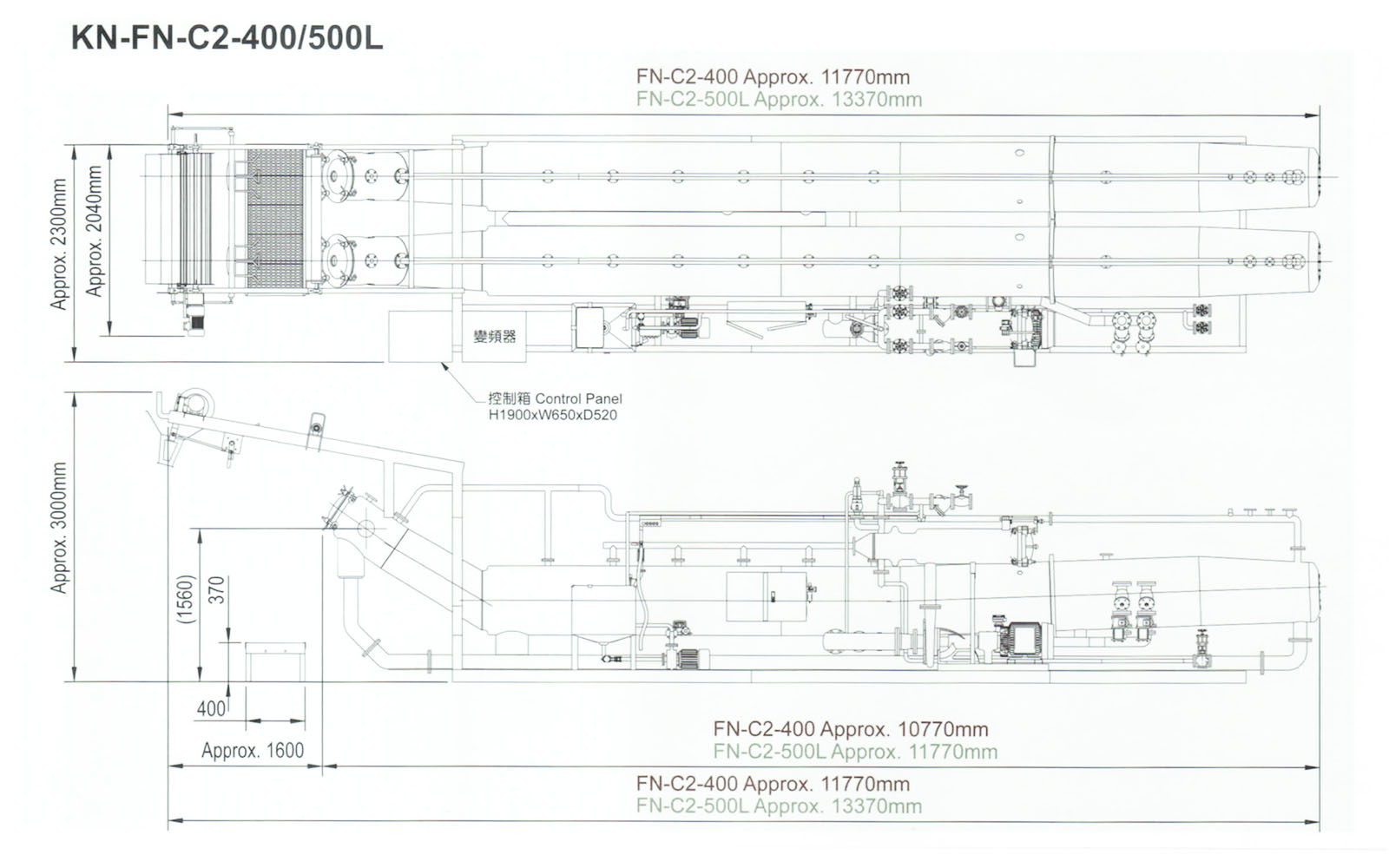

| KN-FN-C1-180 | KN-FN-C1-200 | KN-FN-C2-400 | KN-FN-C4-800 | KN-FN-C1-250L | KN-FN-C2-500L | KN-FN-C4-1000L | ||

| Max. Pressure | kg/cm² | 4~5 | 4~5 | 4~5 | 4~5 | 4~5 | 4~5 | 4~5 |

| Max. Temperature | °C | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Liquor | Lit. | 500 | 800~1200 | 1600~2400 | 3200~4800 | 800~1500 | 1600~2700 | 4200~6000 |

| Capacity Weight | kg | 30~80 | 120~200 | 240~400 | 480~800 | 120~250 | 240~500 | 500~1000 |

| Thin Cloth Length | m | 350 | 1000 | 2000 | 4000 | 1100 | 2200 | 4400 |

| Power | kw | 25 | 30 | 45 | 60 | 30 | 50 | 75 |

| Fabric Speed | m/min | 150~500 | 150~500 | 150~500 | 150~500 | 150~500 | 150~500 | 150~500 |

| Heating Rate | min | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Cooling Rate | min | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Cooling Water Consumption | ton | 1 | 1.5 | 3 | 6 | 2 | 4 | 8 |

| Steam Consumption | kg | 160 | 250 | 442 | 900 | 290 | 500 | 1000 |

| Air-Capacity | m² | 2 | 2.2 | 4.4 | 8.8 | 2.72 | 5.5 | 11 |

*We reserve the right to make amendment without any further notification.

*We reserve the right to make amendment without any further notification.